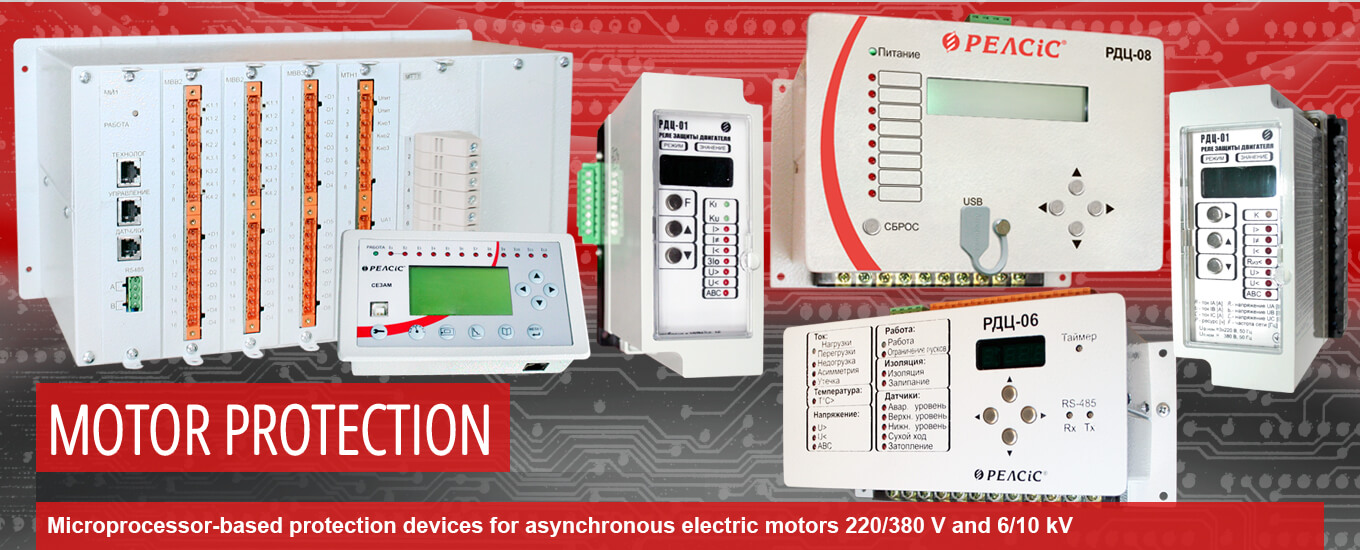

Motor Protection

Motor protection microprocessor relays for motors 0,4 kV

in Networks with Insulated Neutral

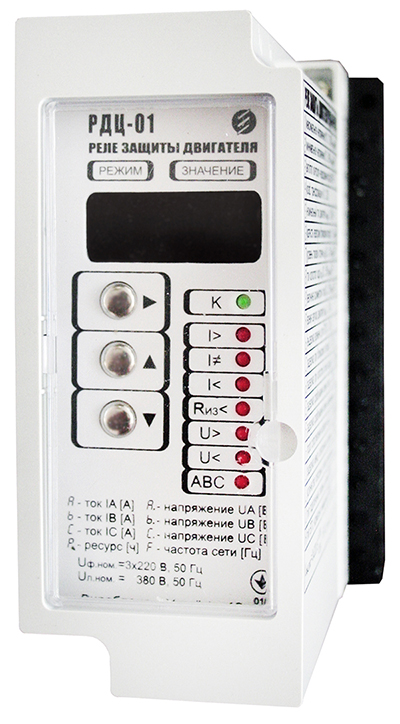

RDC-01-053, RDC-01-203

The relays of engine protection RDC-01-053, RDC-01-203 (with digital control and indication of controlled parameters) are intended for protection of three-phase asynchronous electric motors of 3х380 V 50 Hz with direct connection by the power (0,55...2,2) kW (RDC-01-053), (2,2...9,0) kW (RDC-01-203) and with connection via measuring transformers of current with the power (9,0...450) kW (RDC-01-053).

Relays carry out protection of the electric motor against consequences (protective functions of the relays):

- overloading;

- asymmetry of loading;

- underrunning;

- supply overvoltage;

- supply undervoltage;

- wrong phase rotation;

- decrease of the isolation resistance of engine windings before start-up and circuit switching at reaching of one of controlled parameters of the programmed level.

Service functions of the relays:

- possibility of monitoring of the following parameters:

- consumption current on each phase (IA, IB, IC);

- voltage in electric network on each phase (UA, UB, UC);

- network frequency;

- motor-meter;

- anomalies in networks and the reasons of critical conditions. - the adjusted number of automatic start-ups after emergency shutdown (up to five start-ups with time interval between repeated start-ups - 15 s);

- protection of the adjusted settings against unauthorized access (password);

- possibility of removal of the kept accident parameters without device shutdown.

Motor protection microprocessor relays for motors 0,4 kV

RDC-01-055, RDC-01-205

The relays of engine protection RDC-01-055, RDC-01-205 (with digital control and indication of controlled parameters) are intended for protection of three-phase asynchronous electric motors of 3х380 V 50 Hz with direct connection by the power (0,55...2,2) kW (RDC-01-055), (2,2...9,0) kW (RDC-01-205) and with connection via measuring transformers of current with the power (9,0...450) kW (RDC-01-055).

Relays carry out protection of the electric motor against consequences:

- overcurrent conditions;

- rotor blocking;

- asymmetry of loading;

- underrunning;

- supply overvoltage;

- supply undervoltage;

- short-circuit (current cutoff);

- return phase rotation;

- decrase of the isolation resistance of engine windings before start-up.

The relays carry out circuit switching at reaching of one of controlled parameters of the programmed level.

The relays have an opportunity to turn off action of the following functions:

- protection against the maximum voltage;

- protection against the minimum voltage;

- protection against the no-load/dry course;

- protection against an asymmetry of current;

- current cutoff;

- protection against the rotor blocking;

- protection against the wrong phase rotation;

- protection against the isolation resistance.

The relays can be used for work in one of two modes:

- current control in phases А, В и С;

- current control in phases А и С.

At the same time, except protective functions, the relays have the possibility of monitoring of the following parameters:

- current consumption in each phase (IA, IB, IC);

- network voltage in each phase (UA, UB, UC);

- the isolation resistance before the motor start-up;

- network frequency;

- motor-meter.

Protection microprocessor relays for motors 0,4 – 6/10 kV

RDC-01-057

The relays of engine protection RDC-01-057 (with digital control and indication of controlled parameters) are intended for the protection of asynchronous electric motors with voltage 0,4 kV (RDC-01-057-1, RDC-01-057-2, RDC-01-057-3), and also high-voltage electric motors 6/10 кV (RDC-01-057-4, RDC-01-057-5).

The relays have the following types of protection against consequences:

- short circuit (current cutoff) (RDC-01-057-4, RDC-01-057-5);

- overcurrent conditions;

- asymmetry of loading (phases А and С or phases А, В and С);

- underrunning (in phases А and С or in phases А, В and С);

- rotor blocking;

- single-phase-to-ground short circuit at the zero sequence current;

- excess of the supply voltage of the motor;

- decrease of the supply voltage of the motor;

- wrong phase rotation;

- sticking of the motor starter contacts (RDC-01-057-1, RDC-01-057-2, RDC-01-057-3).

| Model | Operational power supply of the relay |

Control of linear supply voltages of the motor |

Control of the motor current |

|---|---|---|---|

| RDC-01-057-1 | Single-phase, AC/DC 100, 110, 220 V, 50 Hz |

no | In phases А and С, zero sequence current control at the connection of external transformer of the zero sequence current |

| RDC-01-057-2 | no | 3х110 V, 50 Hz 3х380 V, 50 Hz |

In phase A and C |

| RDC-01-057-3 | Single-phase, AC/DC 100, 110, 220 V, 50 Hz |

In phases А, B, С | |

| RDC-01-057-4 | Single-phase, AC/DC 100, 220 V, 50 Hz |

no | In phases А and С, zero sequence current control at the connection of external transformer of the zero sequence current |

| RDC-01-057-5 | 3х110 V, 50 Hz | In phases А and С |

Model range of the motor protection microprocessor relays

RDC-02, RDC-03, RDC-04, RDC-05, RDC-06

The relays RDC-02, RDC-03, RDC-04, RDC-05, RDC-06 are intended for complex protection and control by three-phase asynchronous engines of 3 (220/380)V (including submersible pumps) with indication of the reasons of accidents, information transfers on control offices, automatic repeated start-up and a possibility of automatic connection of a reserve and duplication.

The presented model range allows to protect asynchronous engines from consequences:

- long on time but small current overloads;

- big pulse overloads (short-circuit rotor);

- excess of an asymmetry level of the phase currents;

- underrunning;

- excess of the supply voltage (except RDС-02);

- decrease of the supply voltage (except RDС-02);

- earth current;

- wrong (reverse) phase rotation before start-up (except RDС-02);

- decrease of the motor isolation resistance before start-up;

- sticking of motor starter contacts before start-up;

- phase break;

- inadmissible temperature increase of the motor enclosure.

At the same time, except protective functions, the relays have the possibility of monitoring of the following parameters:

- consumption current on each phase (IA, IB, IC);

- electric network voltage on each phase (UA, UB, UC) (except RDC-02);

- network frequency;

- motor current temperature;

- the value of the asymmetry of the phase current;

- earth current;

- the motor isolation resistance before start-up;

- the value of an equivalent of thermal energy;

- the general operating time of the motor;

- cosφ motor (RDC-04, RDC-06 only);

- motor active power (RDC-04, RDC-06 only);

- motor reactive power (RDC-04, RDC-06 only);

- motor gross power (RDC-04, RDC-06 only);

Purpose of devices

- RDC-02 - the current relay with operational supply power (it can be used for protection of electric motors 0,4/6/10 of kV);

- RDC-03 - universal protection of common industrial motors with the maximum necessary set of the protection functions;

- RDC-04 - universal protection of common industrial motors; it remotely carries out monitoring of all current parameters, reads out information from the magazine where working and emergency events (up to 100) are fixed, makes control of output relays and controls current state of RDTs by means of RS485 under the Modbus RTU protocol and the software "Relsis motor config" which is included in the delivery package; it has an expanded set of functions of protection and service;

- RDC-05 - universal protection of motors of deep pumps and pump stations with the maximum necessary set of protection functions and with inputs for connection of sensors: emergency, top, lower levels, the dry course, flooding for implementation of automatic inflating or pumping out of liquid, filling/depletion of the tank bulks, etc.;

- RDC-06 - universal protection of motors of deep pumps and pump stations; it carries out remote control of a condition of all current parameters and sensors, reads out information from the magazine of events (up to 100); it operates the engine via the RS485 interface under the Modbus RTU protocol and software "Relsis motor config", can also switch on/switch off the engine using the timer; it has an expanded set of functions and service.

Distinctive characteristics of a model range RDC-02...RDC-06

| Device functions | Models | ||||

|---|---|---|---|---|---|

| RDC-02 | RDC-03 | RDC-04 | RDC-05 | RDC-06 | |

| Rated current, А | 1-1000 | 1-1000 | 1-1000 | 1-1000 | 1-1000 |

| Switching off at the rotor blocking of the electric motor | + | + | + | + | + |

| Switching off at the current overload of the electric motor | + | + | + | + | + |

| Switching off at the underrunning of the electric motor | + | + | + | + | + |

| Switching off at the electric motor working with unacceptable asymmetry of currents | + | + | + | + | + |

| Switching off of electric motor at excess of level of earth current | + | + | + | + | + |

| Switching off of electric motor at current wire tearing off or burning out of the starter contact | + | + | + | + | + |

| Switching off at the supply overvoltage | + | + | + | + | |

| Switching off at the decrease of the supply voltage | + | + | + | + | |

| Switching off of electric motor at the disappearance or tearing off of the voltage phase | + | + | + | + | |

| Prohibition of the switching on at the wrong phase rotation/td> | + | + | + | + | |

| Prohibition of the switching on at the isolation destruction of the electric motor | + | + | + | + | + |

| Restriction of number of repeated activations of the electric motor | + | + | + | + | + |

| Automatic equipment elements | |||||

| Measurement of temperature of the electric motor by external integrated sensor of temperature | + | + | + | + | + |

| Connection of the sensor of the liquid level in the tank | + | + | |||

| Connection of the sensor "dry course" of the electric motor | + | + | |||

| Connection of the sensor of the room flood | + | + | |||

| Logical inputs and outputs for automatic connection of a reserve, duplication and remote control | + | + | + | + | + |

| Service functions | |||||

| Digital indication of operating modes | + | + | + | + | + |

| Output for indicator of overcurrent condition | + | ||||

| Motor control within a day | + | + | + | + | + |

| Possibility of switching off of functions which aren't used | + | + | + | + | + |

| Motor-meter of the electric motor | + | + | + | + | + |

| Measurement of the current operating values of phases currents | + | + | + | + | |

| Measurement of the current operating values of phases voltages | + | + | + | + | + |

| Indication of frequency of supply network | + | + | |||

| Measurement of the current motor power | + | + | |||

| Measurement of cosφ of the electric motor | + | + | |||

| Embedded interface RS-485 | + | + | |||

| Preservation in non-volatile memory of the chronological sequence of the taken place events (up to 100 events) | + | + | |||

| Design | |||||

| Recessed mounting | + | + | + | + | + |

| Protuded mounting | + | + | + | + | + |

Complex Motor Protection up to 450 kW

RDC-08

Advanced relays of protection of electric motors of the RDC-08 series have all advantages of the RDC series and considerably expand borders of its application. These relays are characterized by novelty in the field of the complex solution of protection, control and monitoring of electric equipment with electric motors of 0,4 kV and with power from 2,2 to 450 kW

Construction

The RDC-08 relay is manufactured in the metal enclosure which consists of a casing, the basis with ranks of clips for connection of current chains, chains of linear voltage which are connected to the enclosure on the device back. The relay contains terminals under the M4 screw for connection of currents of three phases and current 3I0, the supply voltage of 220 V, 50 Hz and also terminals under the M3 screw for connection of three phase-voltages of UA, UB, UC (there is a modification for linear voltage and 3U0), two analog inputs (U=0...10 V and I=5...20 mА) and the digital I2C (SPI) interface for various sensors.

Also there are terminals under the M3 screw for connection of chains of 4 output relays and 8 discrete inputs which are controlled by means of "dry contact" from the internal power supply. All connections are galvanic isolated.

Modifications

- For projection mounting with forward connection of wires;

- For recessed mounting with back connection of wires;

Functions

- Maximum current protection with independent and dependent characteristics;

- Current cutoff;

- Protection against mechanical overloads;

- Protection against sustained start-up;

- Protection against rotor blocking;

- Protection against current asymmetry of phases;

- Protection against current excess of the return sequence;

- Protection against earth current (ground short-circuit of stator winding in operating time);

- Protection for the minimum operating current ("dry course" - for the pumps);

- Protection against overvoltage;

- Low-voltage protection;

- Protection against phases breakage;

- Protection against distortion of phase voltage;

- Protection against distortion of phase rotation and sticking phases before start-up;

- Protection against reduction of insulation resistance between stator and enclosure of motor before start-up;

- Protection against excess of temperature of motor enclosure;

- Checking the sticking effect of contacts of the starter before start-up;

- Automatic repeated turning on with controlled delay;

- Remote control of motor;

- Other functions at the request of the customer;

- Data exchange by means of USB and RS-485 Modbus RTU.

Electrical Machine Protection and Control Device

SEZAM-М

The device of protection and monitoring of the electrical machines SEZAM-M is intended for use in schemes of technological and relay protection of asynchronous electrical machines of alternating current of 6-10 kV and with power up to 5 MW.

The devices of the SEZAM series are based on the most modern principles. The logic of functioning of the device is formed on the basis of library of the standard ANSI functions with use of modern open languages of high level. The modular principle of creation of a configuration allows to optimize it according to the required task that gives the chance to reach the best indicators "price/functionality".

The devices of the SEZAM series possess all standard functions of microprocessor protection, namely: functions of protection, measurement, automatic equipment, diagnostics of network and the switching device, self-diagnostics, a digital oscillography and communication under the open MODBUS protocol. At the same time it is necessary to emphasize that the device, conforming to all necessary requirements to perspective development of system, has no excess functions that allows to provide an optimum ratio of the price and quality.

Control Stations of Motor Protection

of the SUZD series

Stations of the SUZD series are intended for harmonious association of functions of protection, automatic control, the alarm system, indication, monitoring of work with function of economy of the electric power of three-phase asynchronous electric motors, pumps, fans, compressors, the lifting and transport equipment, industrial facilities with supply voltage 3x220/380 V with power from 0,25 to 320 kW.

SUZD series

- SUZD-01...06 - Control stations of motor protection based on microprocessor protection;

- SUZD-P - Control stations of motor protection with gradual start-up;

- SUZD-CH - Control stations of motor protection with using of frequency converter;

- SUZD-М - Control stations of motor protection with integration in APCS;

- SUZD-ТЕ - Control stations of motor protection based on the solid-state relays and thermal protection;

- SUZD-Т - Control stations of motor protection on thermal protection.

Control stations SUZD allow to:

- create completely automatic mode of control of drives with a possibility of remote measurement of parameters, the analysis of the modes, recording and preservation of parameters of production cycles;

- look through all current measured values at any moment in the place and on telemetry on the computer;

- define the most effective operating modes for optimization of a resource of the motor, consumption of the electric power and work of personnel, using the operational and saved-up information of SUZD;

- carry out accounting (not commercial) of the consumed electric energy and signaling of telemetry in the system of technical accounting of the top level;

- perform functions of local automation of technological process;

- carry out transfer of emergency signals to an automatic control system of the top level;

- carry out receiving and processing of the operating signals from an automatic control system of the top level;

- carry out displaying of electric parameters, conditions of loading and operating time, a possibility of remote configuration and control from the remote workstation;

- install the portable terminal on a case door;

- install the built-in serial port RS485 for connection to the bus with the ModBus RTU protocol.