Contract Manufacturing of Electronics

Our main strategy is to take care of the complete production cycle of your product. In the modern world of electronics the customer does not even have to develop a product, but it is enough to create an idea and explain it to the manufacturer. We have everything we need to turn your idea into a finished serial product.

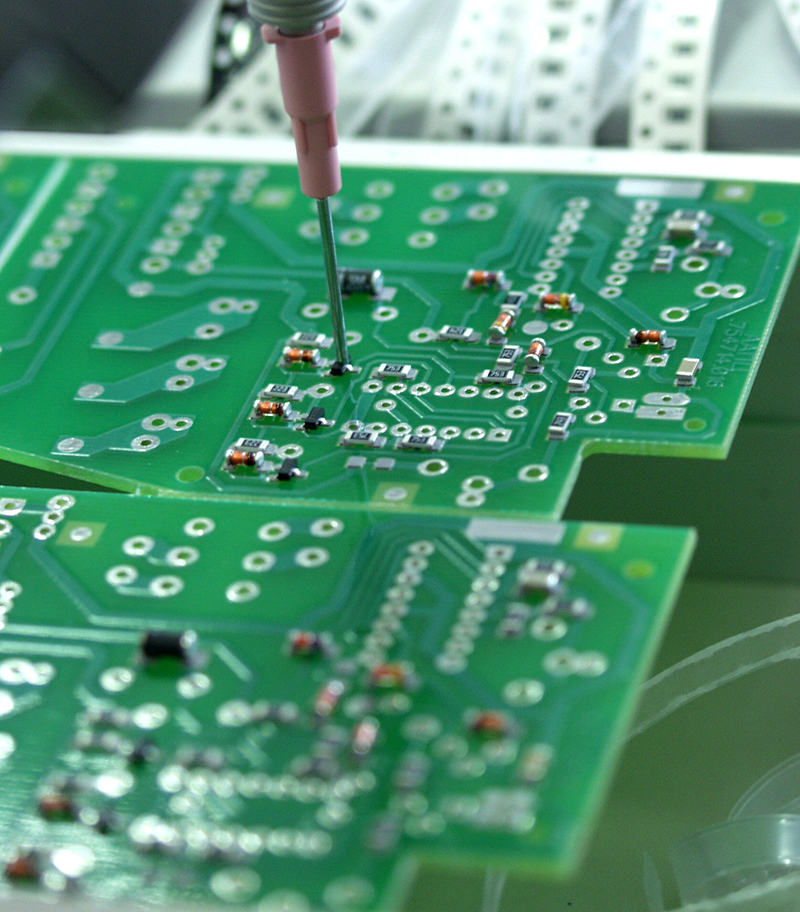

The powerful complex of modern technological equipment, as well as flexible technological process of assembly of products allows us to install all types of surface components (PBGA, PCSP, PLCC, QFP, SOIC, Chip) using modern soldering technologies. Assembly of products is possible with the application of both classical and lead-free technology of montage of electronics products.

Our production capabilities are as follows:

Surface mounting of printed circuit boards.

Location of components on the automatic equipment Universal AdVantis AC-72 (USA), melting in the 8-zone furnace of convection soldering Vitronics Soltec XPM² (USA). Location of components on the semi-automatic machine FRITSCH LM901 (Germany) and melting in the 3-zone conveyor convection furnace MISTRAL 260 (Germany).

Through hole technology: forming, installation, soldering of DIP-components. Washing of printed circuit boards in a bath with a washing liquid and use of ultrasound.

Manufacture of inductance coils for chokes or transformers. Winding is carried out by means of enameled wire (wire diameter – 0,03 ... 0,71 mm) on coils with diameter up to 110 mm and length up to 160 mm.

Manufacture of special terminals with screw clamps. The terminals allow you to locate various small electrical products on them and connect them to the wires. The number of screw connections - up to 20 pcs. Screw clamps are made of L63 material with thickness of 1,0 … 2,0 mm.

Application of marking by silk-screen or tampo printing and also by thermal printer.

Application of protective coatings by spraying.

Checking, setting up and testing of finished products.

The following information is required to determine the cost of the order for the installation of printed circuit boards:

- Printed circuit board (PCB) design file in PCAD format (version 2000 or higher), Protel format or GERBER format (all layers required for PCB manufacturing and stencil manufacturing are required).

- The full file specification (the full list of elements) in the form of text information in Word, Excel or as a table according to the unified system of design documentation. The specification must contain:

- Position designation of the component;

- Component name;

- Nominal value of the component;

- Number of components;

- Component housing type;

- Pick&Place file;

- Assembly drawing of the module or a well readable mounting diagram of all elements;

- Technical requirements for mounting, washing off and inspection:

- components to be installed after mounting;

- components that cannot be washed in a bath or in an ultrasonic bath;

- uninstalled components (mark - do not install).

Design of multilayer printed-circuit boards нon the basis of the scheme and target specification. Optimization of the PCB according to the customer's requirements. Professional level of the employees possessing knowledge in the field of digital, analog and high-frequency circuit engineering, allows to interact optimally with developers, to understand all nuances of the task, to offer the best variants of technical decisions at designing of complicated PCBs.

The whole spectrum of radio electronics production includes the following areas:

- Production of electronic products for various purposes and complexity.

- Mounting of SMD-components using the most modern technologies and equipment.

- Mounting of output components. Selection of soldering technology depending on number and location of output elements, their complexity, order quantity.

- Manufacture of coiling products used in devices and electrical equipment.

- PCB washing including ultrasonic cleaning systems.

- The use of waterproof coatings in electronic products that operate in extreme climatic conditions (large temperature differences, the influence of chemically aggressive environments, high humidity and dust).

- Testing and adjustment of manufactured electronic products. Multilevel quality control system guarantees reliability of operation of finished devices and equipment.

- Housing location.

- Packaging of electronic products. The choice of packaging materials and container sizes depends on the requirements for transporting electrical equipment.

Your needs contribute to the development of our capabilities.

Now at the enterprise there is a process of replacement of the equipment on more technological and modern one. For consideration we accept any offers to cooperation with the customer on manufacturing of demanded production.

Contact person (concerning contract manufacturing):

Vitaliy Polyakovskiy

ph. number: +38 (044) 500-61-46

e-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.